The team, consisting of nine researchers from the University of Illinois at Urbana-Champaign, the University of Chicago and Hanyang University in Korea, was able to increase the resolution of their intricate structure fabrication from approximately 200 nanometers to approximately 15 nanometers. A nanometer is a billionth of a meter, the width of a double-stranded DNA molecule.

The ability to fabricate nanostructures out of polymers, DNA, proteins and other "soft" materials has the potential to enable new classes of electronics, diagnostic devices and chemical sensors. The challenge is that many of these materials are fundamentally incompatible with the sorts of lithographic techniques that are traditionally used in the integrated circuit industry.

Recently developed ultrahigh resolution ink jet printing techniques have some potential, with demonstrated resolution down to 100-200 nanometers, but there are significant challenges in achieving true nanoscale dimension. "Our work demonstrates that processes of polymer self-assembly can provide a way around this limitation," said John Rogers, the Swanlund Chair Professor in Materials Science and Engineering at UIUC.

Rogers and his associates report their findings in the September issue of Nature Nanotechnology. Combining jet printing with self-assembling block copolymers enabled the engineers to attain the much higher resolution, as suggested by lead author Serdar Onses, a postdoctoral scientist at UIUC. Onses earned his doctorate at the University of Wisconsin under Paul Nealey, now the Brady W. Dougan Professor in Molecular Engineering at UChicago and a co-author of the Nature Nanotechnology paper. "This concept turned out to be really useful," Rogers said.

Engineers use self-assembling materials to augment traditional photolithographic processes that generate patterns for many technological applications. They first create either a topographical or chemical pattern using traditional processes. For the Nature Nanotechnology paper, this was done at imec in Belgium, an independent nanoelectronics research center. Nealey's laboratory pioneered this process of directed self-assembly of block copolymers using chemical nanopatterns.

Nearing the limits

The resolution of the chemical pattern nears the current limit of traditional photolithography, noted Lance Williamson, a graduate student in molecular engineering at UChicago and co-author of the Nature Nanotechnology article. "Imec has the capability to perform the photolithography at this scale over large areas with high precision," Williamson said.

Back at UIUC, engineers place a block copolymer atop this pattern. The block copolymer self-organizes, directed by the underlying template to form patterns that are at much higher resolution than the template itself.

Previous work has focused on the deposition and assembly of uniform films on each wafer or substrate, resulting in patterns with essentially only one characteristic feature size and spacing between features. But practical applications may need block copolymers of multiple dimensions patterned or spatially placed over a wafer.

"This invention, to use inkjet printing to deposit different block copolymer films with high spatial resolution over the substrate, is highly enabling in terms of device design and manufacturing in that you can realize different dimension structures all in one layer," Nealey said. "Moreover, the different dimension patterns may actually be directed to assemble with either the same or different templates in different regions."

Benefits of e-jet printing

The advanced form of inkjet printing the engineers use to locally deposit block copolymers is called electrohydrodynamic printing, or e-jet printing, which operates much like the inkjet printers office workers use for printing on paper. "The idea is flow of materials from small openings, except e-jet is a special, high-resolution version of ink-jet printers that can print features down to several hundred nanometers," Onses said. And because e-jet can naturally handle fluid inks, it is exceptionally well suited for patterning solution suspensions of nanotubes, nanocrystals, nanowires and other types of nanomaterials.

"The most interesting aspect of this work is the ability to combine 'top down' techniques of jet printing with 'bottom up' processes of self-assembly, in a way that opens up new capabilities in lithography -- applicable to soft and hard materials alike," Rogers said.

"The opportunities are in forming patterned structures of nanomaterials to enable their integration into real devices. I am optimistic about the possibilities."

Wednesday, 18 September 2013

Invention Jet Prints Nanostructures With Self-Assembling Material

Sunday, 15 September 2013

Putting a Seal of Security On the Internet of Services:

IoS('Internet of Services') is a vision of the future internet in which information, data and software applications -- and the tools to develop them -- are always accessible, whether locally stored on your own device, in the cloud, or arriving in real time from sensors. Whereas traditional software applications are designed largely to be used in isolation, IoS brings down the barriers, thereby lowering costs and stimulating innovation.

Building on the success of cloud computing, IoS applications are built by composing services that are distributed over the network and aggregated and consumed at run-time in a demand-driven, flexible way. This new approach to software will make the development of applications and services easier -- so that new and innovative services, not possible today, can be offered. It is likely to make a huge contribution to the EU's strategy to make Europe's software sector more competitive.

IoS services can be designed and implemented by producers, deployed by providers, aggregated by intermediaries and used by consumers. Anybody who wants to develop applications can use the resources in the Internet of Services to develop them, with little upfront investment and the possibility to build upon other people's efforts.

In many ways IoS solves the challenges of interoperability and inefficiency that can plague traditional software systems, but it can also create new vulnerabilities. How for instance can you trust that a service you are using is error free? Or that the different components from different developers that you are aggregating into a new application have all been tested for security vulnerabilities?

'Although it is always difficult to quantify exactly the impact of the absence of something, it is clear that the lack of efficient security validation technologies has been slowing down considerably the wide adoption of web services by citizens, many of whom still do not trust the internet in general nor the Internet of Services in particular,' warns Professor Luca Viganò at the Universita Degli Studi di Verona in Italy. 'It is thus not enough to develop good web-based services, nor to develop services that have been proved secure or which have been tested, but rather we also need a way to convince the citizen that they are indeed secure or have been thoroughly tested. The existence and use of automated tools that can put their "seal of guarantee" on newly developed services, or on services that have been downloaded from the web, will certainly guarantee higher confidence and trust.'

Prof. Viganò and a team of researchers from five European countries are putting the finishing touches on tools to provide precisely that much-needed 'seal of guarantee' on web services. Their work, carried out in the 'Secure provision and consumption in the Internet of Services' (SPACIOS) project and supported by EUR 3.6 million in research funding from the European Commission, combines novel, state-of-the-art technologies for penetration security testing, vulnerability-driven security testing, mutation-based security testing, automatic learning for model inference, model checking and code extraction techniques.

A unique tool for security testing web services

'It is important to note that state-of-the-art security validation technologies exist, but they are typically used in isolation and at production time, whereas we need tools that can be employed to validate services at run-time,' Prof. Viganò explains. 'There are a number of other tools that have been used extremely proficiently for security testing, but none, to our knowledge, that combines all these techniques into one single tool, using one single formal language in input and output. The SPACIOS tool, we believe, possesses capabilities that no other tools exhibit.'

In grossly simplified terms, a user starts with a formal specification of the system to be tested in which its properties are specified as logical formulae. If no formal specification exists, the SPACIOS tool can generate a model automatically from the source code. The model is then tested for vulnerabilities using a state of the art model-checking platform called AVANTSSAR (that Prof. Viganò helped develop in a previous project).

If an attack is found, the model checker outputs an attack trace, which can be used to generate test cases for the system. If no attack is found, the model is mutated to force standard vulnerabilities in the specification and the tests are repeated. Any attack traces that are uncovered are used to generate test cases, which are then run against the system again. The process is repeated until all parameters and potential security vulnerabilities have been checked.

'It is important to note that the different components of the tool can be used separately, they are integrated into an Eclipse platform, which allows the user to choose what exactly they wish to do,' the SPACIOS coordinator says.

The team tested the tool in various industry-relevant application scenarios with real-world applications. They looked, for example, for security vulnerabilities in SAML 2.0 Web Single Sign-on (an emerging standard that enables online business partners to authenticate their users once within a federated identity environment) and in OpenID (an open and user-centric web-browser-based Single Sign-On protocol that provides a way to authenticate a user by asking them to prove that they control a unique identifier). Among other scenarios, they also applied the SPACIOS Tool to a set of open-source web applications that include an online bookstore, a site for classifieds and an employee directory. These web applications have previously been used as targets for both source code analysis and vulnerability testing.

Siemens and SAP, German industrial partners involved in SPACIOS, also put forward three other applications scenarios to validate the tool: Pervasive Retail (which contains a novel on-demand marketing management platform to create interactivity between consumers, retailers, and product providers through mobile phones), Infobase Document Repository (which implements a Document Management System that allows for the secure management and sharing of documents or data files using web browsers) and eHealth (based on mash-up systems that on the one hand create and use electronic health records and on the other hand aggregate other functionalities, like decision support for the practitioner, analysis of images and billing systems).

Given the breadth of the Internet of Services and its likely rapid expansion over the coming years, the potential application scenarios for the SPACIOS tool are almost endless. Deployed widely, it would provide users with better security and lower web service development costs considerably.

'The SPACIOS approach will allow for smooth integration within the service development cycle, ranging from analysis at design time to testing at run-time, thus allowing developers to considerably reduce their costs. It is difficult to estimate this quantitatively, but we expect to be able to provide some measures once the integration has been taken up by the projects' industrial partners,' Prof. Viganò explains.

Though the partners have no immediate plans to directly commercialise the tool, it is already being used in industry by Siemens, SAP and others, Prof. Viganò says. The project partners are also discussing the possibility of a follow-up project to further enhance the fault and vulnerability testing technology.

Friday, 13 September 2013

Scientists Achieve Highest Open-Circuit Voltage for Quantum Dot Solar Cells:

"These results clearly demonstrate that there is a tremendous opportunity for improvement of open-circuit voltages greater than one volt by using smaller QDs in QD solar cells," said Woojun Yoon, Ph.D., NRC postdoctoral researcher, NRL Solid State Devices Branch. "Solution processability coupled with the potential for multiple exciton generation processes make nanocrystal quantum dots promising candidates for third generation low-cost and high-efficiency photovoltaics."

Despite this remarkable potential for high photocurrent generation, the achievable open-circuit voltage is fundamentally limited due to non-radiative recombination processes in QD solar cells. To overcome this boundary, NRL researchers have reengineered molecular passivation in metal-QD Schottky junction (unidirectional metal to semiconductor junction) solar cells capable of achieving the highest open-circuit voltages ever reported for colloidal QD based solar cells.

Experimental results demonstrate that by improving the passivation of the PbS QD surface through tailored annealing of QD and metal-QD interface using lithium fluoride (LiF) passivation with an optimized LiF thickness. This proves critical for reducing dark current densities by passivating localized traps in the PbS QD surface and metal-QD interface close to the junction, therefore minimizing non-radiative recombination processes in the cells.

Over the last decade, Department of Defense (DoD) analyses and the department's recent FY12 Strategic Sustainability Performance Plan, has cited the military's fossil fuel dependence as a strategic risk and identified renewable energy and energy efficiency investments as key mitigation measures. Research at NRL is committed to supporting the goals and mission of the DoD by providing basic and applied research toward mission-ready renewable and sustainable energy technologies that include hybrid fuels and fuel cells, photovoltaics, and carbon-neutral biological microorganisms.

Nano-Optics: Integrated Optical Circuits Coming Soon?

Optical fibers are now delivering ultrafast internet connections to homes across the world. By replacing electronics-based technologies with architectures that process pulses of light, a similar leap in speed might also be possible for other forms of information handling. To realize this potential, scientists must first develop novel devices that are capable of controlling the flow of light at the nanometer scale.

Such a device may now be within reach. Yuan Hsing Fu at the A*STAR Data Storage Institute and co‐workers have demonstrated a unique optical effect in nanoparticles that allows them to control the direction in which visible light scatters1.

Miniaturization is key to the success of modern-day electronics: complicated circuitry must be made to fit into portable devices. Likewise, the hardware for processing optical signals must also be miniaturized. In this field, known as photonics, the design of optical components requires an entirely new approach.

The effect demonstrated by Fu and co-workers reveals how nanoparticles can be used to scatter light controllably in the visible spectral range. The researchers first designed a method to measure the scattering, and then fired light at tiny spheres of silicon. When the beam hit a sphere, some scattered backward and some scattered forward. The researchers also showed that it is possible to control the ratio of movement in the two directions by changing the diameter of the nanosphere.

Using silicon spheres with diameters of between 100 and 200 nanometers, the team observed that the amount of forward-scattered light varied from being roughly equal to the amount that was backward-scattered to being six times more intense. They also found that the effect could split the light according to wavelength: for example, nanoparticles of a particular size that backscattered predominantly green light also forward scattered mainly yellow radiation (see image).

The researchers chose silicon over the more conventional choice of a metal such as gold because it reduces energy loss and can influence both the electric and magnetic components of light. The 'preferential' scattering of radiation arises because of the mutual interaction between the electric and magnetic resonances of the nanosphere.

This effect is analogous to that of a radio-frequency antenna. "The experimental proof of such relatively simple nano-optical systems with both an electric and magnetic response in the optical spectral range could pave the way to scaling the optical nano-antenna concept down to a single nanoparticle," says Fu. Optical nanoscale antennas could be useful for improving solar cells and might form a crucial building block for integrated optical circuits.

Wednesday, 11 September 2013

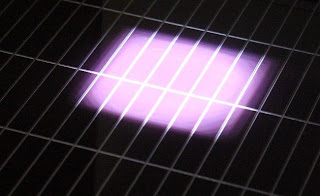

New Kind of Ultraviolet LED Could Lead to Portable, Low-Cost Devices:

The patent-pending LED creates a more precise wavelength of UV light than today's commercially available UV LEDs, and runs at much lower voltages and is more compact than other experimental methods for creating precise wavelength UV light.

The LED could lend itself to applications for chemical detection, disinfection, and UV curing. With significant further development, it might someday be able to provide a source for UV lasers for eye surgery and computer chip manufacture.

In the journal Applied Physics Letters, Ohio State engineers describe how they created LEDs out of semiconductor nanowires which were doped with the rare earth element gadolinium.

The unique design enabled the engineers to excite the rare earth metal by passing electricity through the nanowires, said study co-author Roberto Myers, associate professor of materials science and engineering at Ohio State. But his team didn't set out to make a UV LED.

"As far as we know, nobody had ever driven electrons through gadolinium inside an LED before," Myers said. "We just wanted to see what would happen."

When doctoral students Thomas Kent and Santino Carnevale started creating gadolinium-containing LEDs in the lab, they utilized another patent-pending technology they had helped develop -- one for creating nanowire LEDs. On a silicon wafer, they tailor the wires' composition to tune the polarization of the wires and the wavelength, or color, of the light emitted by the LED.

Gadolinium was chosen not to make a good UV LED, but to carry out a simple experiment probing the basic properties of a new material they were studying, called gadolinium nitride. During the course of that original experiment, Kent noticed that sharp emission lines characteristic of the element gadolinium could be controlled with electric current.

Different elements fluoresce at different wavelengths when they are excited, and gadolinium fluoresces most strongly at a very precise wavelength in the UV, outside of the range of human vision. The engineers found that the gadolinium-doped wires glowed brightly at several specific UV frequencies.

Exciting different materials to generate light is nothing new, but materials that glow in UV are harder to excite. The only other reported device which can electrically control gadolinium light emission requires more than 250 volts to operate. The Ohio State team showed that in a nanowire LED structure, the same effect can occur, but at far lower operating voltages: around 10 volts. High voltage devices are difficult to miniaturize, making the nanowire LEDs attractive for portable applications.

"The other device needs high voltage because it pushes electrons through a vacuum and accelerates them, just like a cathode ray tube in an old-style TV. The high-energy electrons then slam into gadolinium atoms, which absorb the energy and re-emit it as light in the UV," Myers explained.

"We believe our device works at significantly less voltage precisely because of the LED structure, where the gadolinium is placed in the center of the LED, exactly where electrons are losing their energy. The gadolinium atoms get excited and emit the same UV light, but the device only requires around 10 volts."

Because the LED emits light at specific wavelengths, it could be useful for research spectroscopy applications that require a reference wavelength, and because it requires only 10 volts, it might be useful in portable devices.

The same technology could conceivably be used to make UV laser diodes. Currently high-powered gas lasers are used to produce a laser at UV wavelengths with applications from advanced electronics manufacturing to eye surgery. The so-called excimer lasers contain toxic gases and run on high voltages, so solid-state lasers are being explored as a lower power -- and non-toxic -- alternative.

As to cost, Kent pointed out that the team grows its LEDs on a standard silicon wafer, which is inexpensive and easily scaled up to use in industry.

"Using a cheap substrate is good; it balances the cost of manufacturing the nanowires," he said.

The team is now working to maximize the efficiency of the UV LED, and the university's Technology Commercialization and Knowledge Transfer Office will license the design -- as well as the method for making specially doped nanowires -- to industry.

This research was sponsored by the National Science Foundation (NSF) and Ohio State's Center for Emergent Materials, one of a network of Materials Research Science and Engineering Centers funded by NSF.

Friday, 6 September 2013

Shining a Little Light Changes Metal Into Semiconductor

This image shows how electrons in the gold nanorods get excited when exposed to light, then are absorbed into a thin film of zinc oxide, changing the properties of the composite from a metal into a semiconductor. Credit: ACS Applied Materials & Interfaces.

With funding from the Washington University International Center for Advanced Renewable Energy and Sustainability (I-CARES), Parag Banerjee, PhD, and Srikanth Singamaneni, PhD, and both assistant professors of materials science, brought together their respective areas of research.

Singamaneni's area of expertise is in making tiny, pebble-like nanoparticles, particularly gold nanorods. Banerjee's area of expertise is making thin films. They wanted to see how the properties of both materials would change when combined.

The research was published online in August in ACS Applied Materials & Interfaces.

The research team took the gold nanorods and put a very thin blanket of zinc oxide, a common ingredient in sunscreen, on top to create a composite. When they turned on light, they noticed that the composite had changed from one with metallic properties into a semiconductor, a material that partly conducts current. Semiconductors are commonly made of silicon and are used in computers and nearly all electronic devices.

"We call it metal-to-semiconductor switching," Banerjee says. "This is a very exciting result because it can lead to opportunities in different kinds of sensors and devices."

Banjeree says when the metallic gold nanorods are exposed to light, the electrons inside the gold get excited and enter the zinc oxide film, which is a semiconductor. When the zinc oxide gets these new electrons, it starts to conduct electricity.

"We found out that the thinner the film, the better the response," he says. "The thicker the film, the response goes away. How thin? About 10 nanometers, or a 10 billionth of a meter."

Other researchers working with solar cells or photovoltaic devices have noticed an improvement in performance when these two materials are combined, however, until now, none have broken it down to discover how it happens, Banerjee says.

"If we start understanding the mechanism for charge conduction, we can start thinking about applications," he says. "We think there are opportunities to make very sensitive sensors, such as an electronic eye. We are now looking to see if there is a different response when we shine a red, blue or green light on this material."

Banerjee also says this same technology can be used in solar cells.

Engineers Make Golden Breakthrough to Improve Electronic Devices

Vikas Berry, William H. Honstead professor of chemical engineering, and his research team have studied a new three-atom-thick material -- molybdenum disulfide -- and found that manipulating it with gold atoms improves its electrical characteristics. Their research appears in a recent issue of Nano Letters.

The research may advance transistors, photodetectors, sensors and thermally conductive coatings, Berry said. It could also produce ultrafast, ultrathin logic and plasmonics devices.

Berry's laboratory has been leading studies on synthesis and properties of several next-generation atomically thick nanomaterials, such as graphene and boron-nitride layers, which have been applied for sensitive detection, high-rectifying electronics, mechanically strong composites and novel bionanotechnology applications.

"Futuristically, these atomically thick structures have the potential to revolutionize electronics by evolving into devices that will be only a few atoms thick," Berry said.

For the latest research, Berry and his team focused on transistors based on molybdenum disulfide, or MoS2, which was isolated only two years ago. The material is made of three-atom-thick sheets and has recently shown to have transistor-rectification that is better than graphene, which is a single-atom-thick sheet of carbon atoms.

When Berry's team studied molybdenum disulfide's structure, they realized that the sulfur group on its surface had a strong chemistry with noble metals, including gold. By establishing a bond between molybdenum disulfide and gold nanostructures, they found that the bond acted as a highly coupled gate capacitor.

Berry's team enhanced several transistor characteristics of molybdenum disulfide by manipulating it with gold nanomaterials.

"The spontaneous, highly capacitive, lattice-driven and thermally-controlled interfacing of noble metals on metal-dichalcogenide layers can be employed to regulate their carrier concentration, pseudo-mobility, transport-barriers and phonon-transport for future devices," Berry said.

The work may greatly improve future electronics, which will be ultrathin, Berry said. The researchers have developed a way to reduce the power that is required to operate these ultrathin devices.

"The research will pave the way for atomically fusing layered heterostructures to leverage their capacitive interactions for next-generation electronics and photonics," Berry said. "For example, the gold nanoparticles can help launch 2-D plasmons on ultrathin materials, enabling their interference for plasmonic-logic devices."

The research also supports the current work on molybdenum disulfide-graphene-based electron-tunneling transistors by providing a route for direct electrode attachment on a molybdenum disulfide tunneling gate.

"The intimate, highly capacitive interaction of gold on molybdenum disulfide can induce enhanced pseudo-mobility and act as electrodes for heterostructure devices," said T.S. Sreeprasad, a postdoctoral researcher in Berry's group.

The researchers plan to create further complex nanoscale architectures on molybdenum disulfide to build logic devices and sensors.

"The incorporation of gold into molybdenum disulfide provides an avenue for transistors, biochemical sensors, plasmonic devices and catalytic substrate," said Phong Nguyen, a doctoral student in chemical engineering, Wichita, Kan., who is part of Berry's research team.

Namhoon Kim, master's student in grain science and industry, Korea,worked on the research as an undergraduate in chemical engineering.

Wednesday, 4 September 2013

Solar Cell Performance Improves With Ion-Conducting Polymer

Drawing their inspiration from photosynthesis, dye-sensitized solar cells offer the promise of low-cost solar photovoltaics and -- when coupled with catalysts -- even the possibility of generating hydrogen and oxygen, just like plants. A study published in August could lead to more efficient and longer-lasting dye-sensitized solar cells, says one of the researchers from KTH Royal Institute of Technology in Stockholm.

A research team that included James Gardner, Assistant Professor of Photoelectrochemistry at KTH, reported the success of a new quasi-liquid, polymer-based electrolyte that increases a dye-sensitized solar cell's voltage and current, and lowers resistance between its electrodes.

The study highlights the advantages of speeding up the movement of oxidized electrolytes in a dye-sensitized solar cell, or DSSC. Also on the team from KTH were Lars Kloo, Professor of Inorganic Chemistry and researcher Muthuraaman Bhagavathi Achari.

Their research was published in the Royal Society of Chemistry's journal, Physical Chemistry Chemical Physics on August 19.

"We now have clear evidence that by adding the ion-conducting polymer to the solar cell's cobalt redox electrolyte, the transport of oxidized electrolytes is greatly enhanced," Gardner says. "The fast transport increases solar cell efficiency by 20 percent."

A dye-sensitized solar cell absorbs photons and injects electrons into the conduction band of a transparent semiconductor. This anode is actually a plate with a highly porous, thin layer of titanium dioxide that is sensitized with dyes that absorb visible light. The electrons in the semiconductor diffuse through the anode, out into the external circuit.

In the electrolyte, a cobalt complex redox shuttle acts as a catalyst, providing the internal electrical continuity between the anode and cathode. When the dye releases electrons and becomes oxidized by the titanium dioxide, the electrolyte supplies electrons to replenish the deficiency. This "resets" the dye molecules, reducing them back to their original states. As a result, the electrolyte becomes oxidized and electron-deficient and migrates toward the cathode to recovers its missing electrons. Electrons migrating through the circuit recombine with the oxidized form of the cobalt complex when they reach the cathode.

In the most efficient solar cells this transport of ions relies on acetonitrile, a low viscosity, volatile organic solvent. But in order to build a stable, commercially-viable solar cell, a low volatility solvent is used instead, usually methoxypropionitrile. The problem is that while methoxypropionitrile is more stable, it is also more viscous than acetonitrile, and it impedes the flow of ions.

But with the introduction of a new quasi-liquid, polymer-based electrolyte (containing the Co3+/Co2+ redox mediator in 3-methoxy propionitrile solvent), the research team has overcome the viscosity problem, Gardner says. At the same time, adding the ion-conducting polymer to the electrolyte maintains its low volatility. This makes it possible for the oxidized form of the cobalt complex to reach the cathode, and get reduced, faster.

Speeding up this transport is important because when slowed down, more of the cobalt complexes react with electrons in the semiconductor anode instead of with the electrons at the cathode, resulting in rapid recombination losses. Speeding up the cobalt lowers resistance and increases voltage and current in the solar cell, Gardner says.

Sunday, 1 September 2013

Transparent Artificial Muscle Plays Music to Prove a Point

No ordinary speaker, it consists of a thin sheet of rubber sandwiched between two layers of a saltwater gel, and it's as clear as a window. A high-voltage signal that runs across the surfaces and through the layers forces the rubber to rapidly contract and vibrate, producing sounds that span the entire audible spectrum, 20 hertz to 20 kilohertz.

But this is not an electronic device, nor has it ever been seen before. Published in the August 30 issue of Science, it represents the first demonstration that electrical charges carried by ions, rather than electrons, can be put to meaningful use in fast-moving, high-voltage devices.

"Ionic conductors could replace certain electronic systems; they even offer several advantages," says co-lead author Jeong-Yun Sun, a postdoctoral fellow at the Harvard School of Engineering and Applied Sciences (SEAS).

For example, ionic conductors can be stretched to many times their normal area without an increase in resistivity -- a problem common in stretchable electronic devices. Secondly, they can be transparent, making them well suited for optical applications. Thirdly, the gels used as electrolytes are biocompatible, so it would be relatively easy to incorporate ionic devices -- such as artificial muscles or skin -- into biological systems.

After all, signals carried by charged ions are the electricity of the human body, allowing neurons to share knowledge and spurring the heart to beat. Bioengineers would dearly love to mesh artificial organs and limbs with that system.

"The big vision is soft machines," says co-lead author Christoph Keplinger, who worked on the project as a postdoctoral fellow at Harvard SEAS and in the Department of Chemistry and Chemical Biology. "Engineered ionic systems can achieve a lot of functions that our body has: they can sense, they can conduct a signal, and they can actuate movement. We're really approaching the type of soft machine that biology has to offer."

The audio speaker represents a robust proof of concept for ionic conductors because producing sounds across the entire audible spectrum requires both high voltage (to squeeze hard on the rubber layer) and high-speed actuation (to vibrate quickly) -- two criteria which are important for applications but which would have ruled out the use of ionic conductors in the past.

The traditional constraints are well known: high voltages can set off electrochemical reactions in ionic materials, producing gases and burning up the materials. Ions are also much larger and heavier than electrons, so physically moving them through a circuit is typically slow. The system invented at Harvard overcomes both of these problems, opening up a vast number of potential applications including not just biomedical devices, but also fast-moving robotics and adaptive optics.

"It must seem counterintuitive to many people, that ionic conductors could be used in a system that requires very fast actuation, like our speaker," says Sun. "Yet by exploiting the rubber layer as an insulator, we're able to control the voltage at the interfaces where the gel connects to the electrodes, so we don't have to worry about unwanted chemical reactions. The input signal is an alternating current (AC), and we use the rubber sheet as a capacitor, which blocks the flow of charge carriers through the circuit. As a result, we don't have to continuously move the ions in one direction, which would be slow; we simply redistribute them, which we can do thousands of times per second."

Sun works in a research group led by Zhigang Suo, the Allen E. and Marilyn M. Puckett Professor of Mechanics and Materials at Harvard SEAS. An expert in the mechanical behaviors of materials, Suo is also a Kavli Scholar at the Kavli Institute for Bionano Science & Technology, which is based at SEAS.

Suo teamed up with George M. Whitesides, a prominent chemist who specializes in soft machines, among many other topics. Whitesides is the Woodford L. and Ann A. Flowers University Professor in the Department of Chemistry and Chemical Biology, co-director of the Kavli Institute at Harvard, and a Core Faculty Member at the Wyss Institute for Biologically Inspired Engineering at Harvard.

"We'd like to change people's attitudes about where ionics can be used," says Keplinger, who now works in Whitesides' research group. "Our system doesn't need a lot of power, and you can integrate it anywhere you would need a soft, transparent layer that deforms in response to electrical stimuli -- for example, on the screen of a TV, laptop, or smartphone to generate sound or provide localized haptic feedback -- and people are even thinking about smart windows. You could potentially place this speaker on a window and achieve active noise cancellation, with complete silence inside."

Sam Liss, Director of Business Development in Harvard's Office of Technology Development, is working closely with the Suo and Whitesides labs to commercialize the technology. Their plan is to work with companies in a range of product categories, including tablet computing, smartphones, wearable electronics, consumer audio devices, and adaptive optics.

"With wearable computing devices becoming a reality, you could imagine eventually having a pair of glasses that toggles between wide-angle, telephoto, or reading modes based on voice commands or gestures," suggests Liss.

For now, there is much more engineering and chemistry work to be done. The Harvard team chose to make its audio speaker out of very simple materials -- the electrolyte is a polyacrylamide gel swollen with salt water -- but they emphasize that an entire class of ionically conductive materials is available for experimentation. Future work will focus on identifying the best combinations of materials for compatibility, long life, and adhesion between the layers.

In addition to Keplinger, Sun, Whitesides, and Suo, coauthors included Keith Choon Chiang Foo, a former postdoctoral fellow at Harvard SEAS, now at the Institute of High Performance Computing in Singapore; and Philipp Rothemund, a graduate student at Harvard SEAS.

This research was supported by the National Science Foundation through a grant to the Materials Research Science and Engineering Center at Harvard University (DMR-0820484) and by the Army Research Office (W911NF-09-1-0476). It was also enabled in part by the Department of Energy (ER45852) and the Agency for Science, Technology, and Research (A*STAR), Singapore.